📘 Introduction

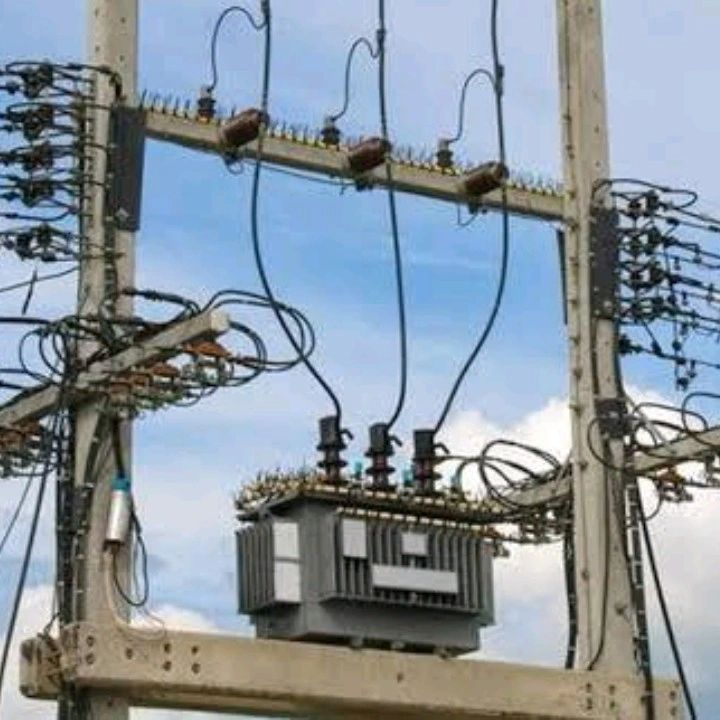

Distribution transformers are vital components of the electrical distribution system, responsible for stepping down voltage to usable levels for end-users. Since they operate continuously and are often exposed to environmental conditions, regular maintenance is essential to ensure reliability, efficiency, and a longer service life.

This article outlines key maintenance tasks, a practical checklist, and professional tips for maintaining distribution transformers effectively.

⚡ Why Transformer Maintenance Matters

Poorly maintained distribution transformers can lead to:

- Power outages

- Voltage fluctuations

- Equipment failure or explosions

- Increased technical losses

- Costly emergency replacements

Proactive maintenance helps ensure safety, reliability, and regulatory compliance.

🧾 Routine Maintenance Checklist

Here’s a detailed maintenance checklist broken down into daily, monthly, quarterly, and yearly tasks.

🔁 Daily/Weekly Checks

| Task | Purpose |

|---|---|

| Visual inspection for leaks/damage | Detect oil leaks, cracks, loose parts |

| Check oil level in conservator | Ensure proper cooling |

| Observe for unusual sounds or smells | Early fault detection |

| Verify temperature gauge readings | Monitor overloading/heating |

📅 Monthly Checks

| Task | Purpose |

|---|---|

| Clean bushings and external surfaces | Avoid tracking, flashovers |

| Check silica gel color in breather | Indicates moisture absorption |

| Confirm physical security | Prevent tampering and theft |

| Inspect for signs of corrosion | Ensure structural integrity |

📆 Quarterly Checks

| Task | Purpose |

|---|---|

| Check oil dielectric strength (BDV) | Assess insulation quality |

| Check grounding connections | Safety and fault path reliability |

| Thermographic inspection (IR camera) | Detect hot spots or loose joints |

| Inspect lightning arresters | Protect against surge failures |

🛠️ Yearly Maintenance

| Task | Purpose |

|---|---|

| Oil testing: BDV, moisture, acidity | Detailed oil health analysis |

| Insulation resistance (IR) testing | Detect winding degradation |

| Tap changer inspection & lubrication | Ensure proper voltage regulation |

| Earth resistance testing | Confirm safe dissipation of faults |

| Tightening of all terminals | Avoid sparking and heating |

| Load analysis and voltage readings | Identify phase imbalance/overload |

🧰 Recommended Tools & Instruments

- Megger for IR Testing

- BDV Test Kit for oil quality

- Thermal Camera for hotspot detection

- Multimeter for voltage/current check

- Earth Resistance Tester

- Oil Test Kit for acidity/moisture

💡 Pro Tips for Maintenance Teams

- Always de-energize the transformer before opening or cleaning.

- Schedule major maintenance during low-demand hours or outages.

- Keep a logbook for each transformer’s test data and observations.

- Replace silica gel when pink or saturated with moisture.

- Use non-metallic brushes or dry cloths for cleaning bushings.

- Install anti-theft devices and fencing in theft-prone areas.

- Implement predictive maintenance using SCADA and IoT sensors where feasible.

⚠️ Common Warning Signs to Watch For

| Sign | Possible Issue |

|---|---|

| Oil level drop | Leak or internal heating |

| Brown/black oil | Internal fault or overheating |

| Cracked or hazy bushing | Moisture ingress |

| Noisy operation | Magnetic core issues or overloading |

| Burnt smell or discoloration | Insulation degradation |

📌 Conclusion

Maintaining distribution transformers is not just about preventing failure—it’s about ensuring continuous, safe, and efficient power delivery. By following a structured checklist and adopting modern diagnostic tools, utilities can greatly reduce unplanned outages, extend transformer life, and improve network performance.