Transformer oil

- Insulating oil in an electrical power transformer is commonly called as transformer oil.

- It can be obtained by fractional distillation and subsequent treatment of crude petroleum.

Transformer oil has the following purposes

- Liquid insulation in electrical power transformer

- Acts as coolant.

- Helps to preserve the core and winding

- Prevents direct contact of atmospheric oxygen with cellulose-made paper insulation(which is susceptible to oxidation)

WATER CONTENT

- Water, in minute quantities, is dangerous in power transformers because it is attracted to the places of greatest electrical stress. Water accelerates the deterioration of both the insulating oil and the paper insulation, liberating more water in the process (heat catalyzed).

- Once the paper insulation is degraded (loss of mechanical strength) it can never (unlike the oil) be returned to its original condition.

Origins of Water

- It can come from two sources. Atmospheric Via the silica gel breather (dry silica gel is always blue). Via leaks into the power equipment, i.e. cracked insulation, bad gaskets, a loose manhole cover, a ruptured explosion diaphragm, etc.

- Internal Sources Paper degradation produces water. Oil degradation produces water. Wet insulation contaminates the oil

DIELECTRIC STRENGTH

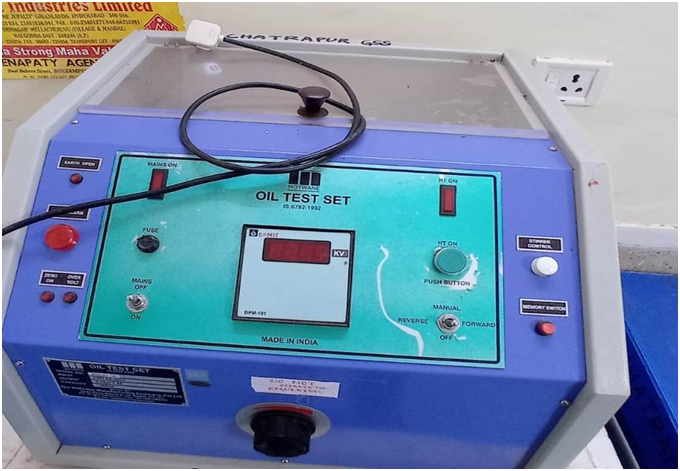

- It is the voltage at which the oil breaks down when subjected to an ac electric field with a continuously increasing voltage contained in specified apparatus.

- Break down voltage is measured by observing at what voltage, sparking starts between two electrodes immersed in the oil, separated by a specific gap.

- BDV is the primary indication of the health of oil and it can be easily carried out at the site which is an important and popular test of transformer oil.

- The low value of BDV indicates the presence of moisture content and conducting substances in the oil.

- Dry and clean oil gives BDV results.

- The minimum breakdown voltage of transformer oil or dielectric strength of transformer oil at which this oil can safely be used in a transformer is considered 30 KV.

Usually, the contaminant is water, but it can also be conductive particles, dirt, debris, insulating particles, and the by-products of oxidation and aging of the oil.

The information gained from the test can also be used as an aid to:

- Remaining life prediction of a transformer

- enhancing operational safety

- Preventing equipment fires

- Maintaining reliability

Dos and Donts for Sample Collection

- For a sample to be truly useful, it must be representative of the oil in the equipment.

- Samples are normally drawn from a drain valve. The drain valve is at the bottom of the equipment, where all of the sludge, water, and contaminant particles collect.

- Before the sample is taken to ensure that dirt does not fall into the sampling container it must be cleaned properly.

- It is important, therefore, to flush the system thoroughly to ensure that the sample is drawn from the main bulk of the oil. This may involve removing two liters of oil, and even more if the equipment has been out of service for some time.

- Do not be tempted to use old engine oil bottles; even a few p.p.m. of engine oil will cause the sample to fail a breakdown test.

- Do let the oil flow down the side of the sample bottle, or use a clean tube to run to the bottom of the bottle; it will prevent air from being mixed with the oil.

- Identifying problems occurring within a transformer is generally performed by analyzing insulating oil taken from transformers. The condition of the transformer can be monitored by identifying and quantifying the gases found in transformer oil.

- If any discrepancies are found, shutdowns can be planned and the fault can be rectified before major damage can occur.

- The interpretation of transformer oil testing should be left to a specialist and his/her advice and recommendations should be followed.

- Samples should be taken regularly and records should be maintained.

- “bad “dielectric readings are mostly due to Careless sampling and testing technique

Regular sampling and testing of insulation oil taken from transformers is a valuable technique in a preventative maintenance program. If a proactive approach is adopted based on the condition of the transformer oil, the life of the transformer can be extended